PTC is an acronym for "positive temperature coefficient."

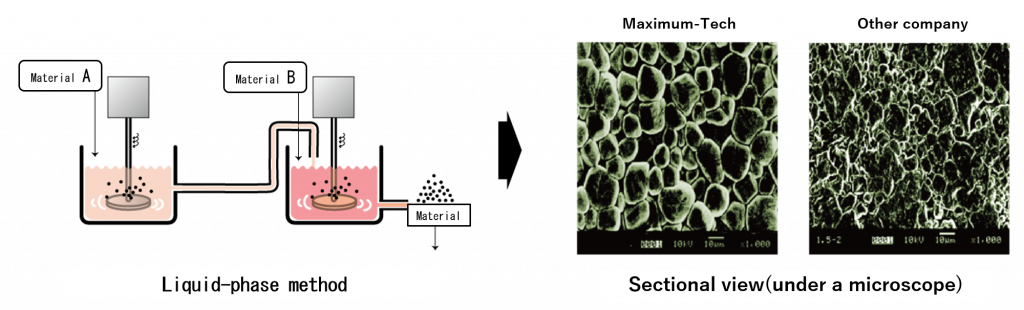

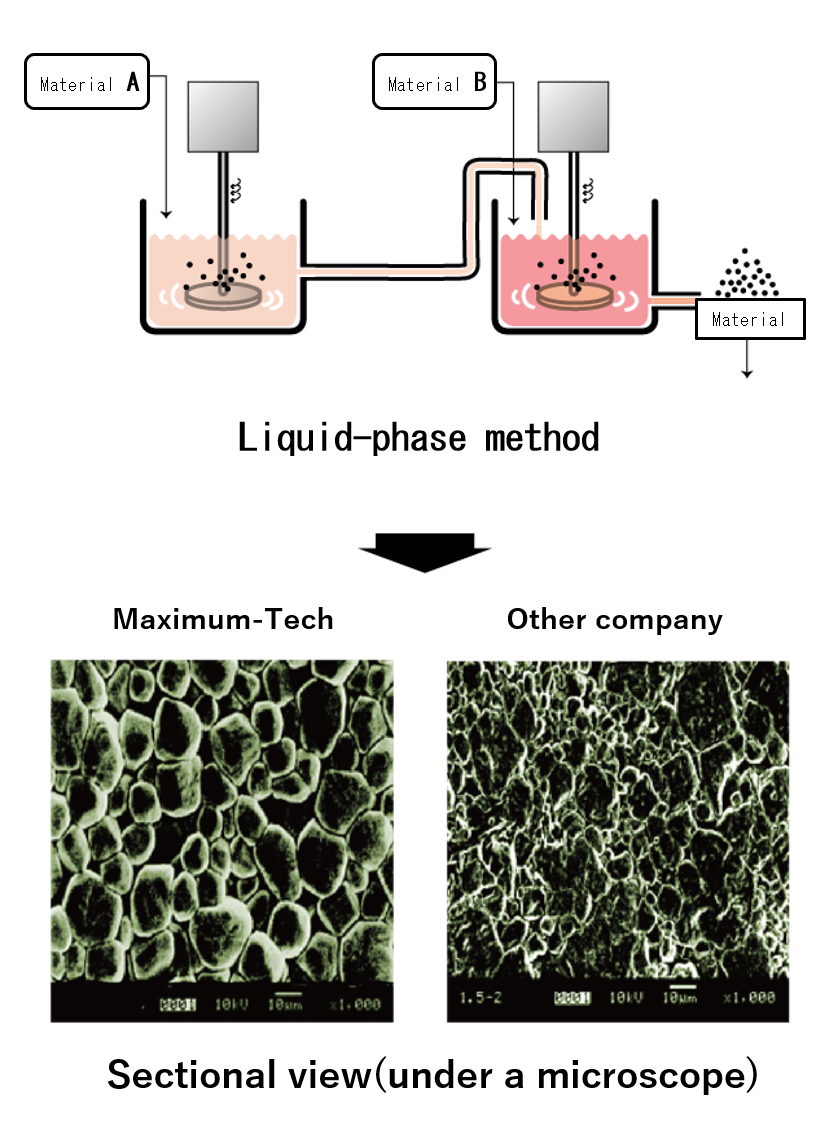

The term "PTC" of PTC Thermistor is abbreviation of Positive Temperature Coefficient and is one of resistor with positive temperature characteristics. PTC Thermistor is also one of Ceramic Semiconductor which signifies its characteristics by adding trace amount of rare earth to Brium Titanate(BaTiO₃)which is one of ferroelectric. The above phenomena were discovered by Dr.Haayman and his collegues in 1951 and the subsequent investigations have been done by its researchers. We, Maximum Technology, have been producing highly-pure raw materials by Liqiuid Phase Manufacturing Method different form the method other manufacturers using and successfully developed low resitance PTC Thermistor (1-3Ω・cm)as strong presence in the world.

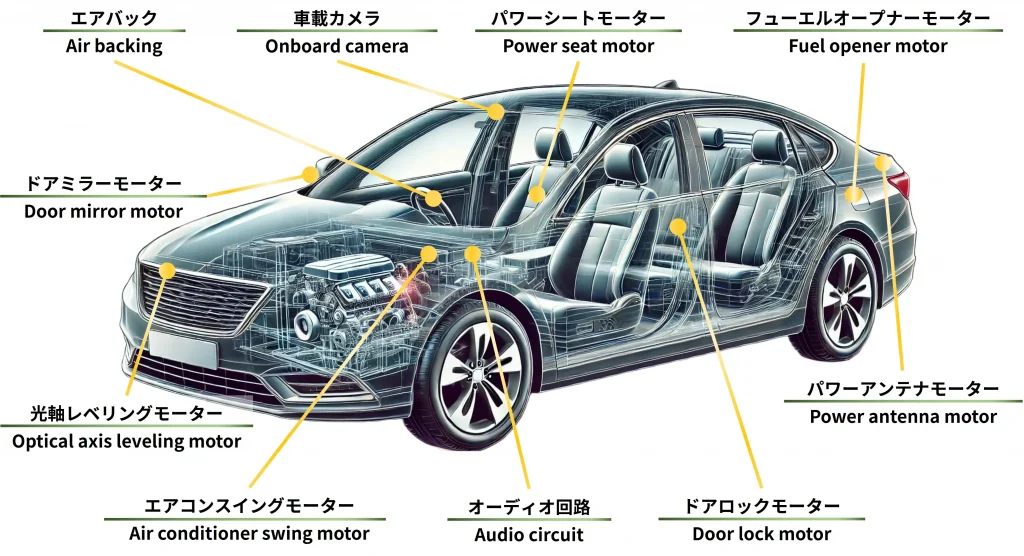

Our PTC Thermistors have been accepted by many users as suitable automotive parts with compat size.

In addition, our Thermistors have been adpted as Engine parts as big power heater.

We, Maximum Technology, are responding quickly for requirements from various customers with packages of every performances (ie. Size, Resistance value, Curie Temperature, etc.) and the range of TC (Curie Temperature) will be varied between 10℃ and 250℃.

Application for PTC Automotive use

Products Utilizing PTC Thermistors

Maximum Technology Co., Ltd. Is to produce PTC devices for overcurrent protection and heaters without cmplex controller by its PTC Thermistor technologies. Maximum Technology Co., Ltd could be designing variuos devices for customers' request in response to state of market .

Basic Features of PTC thermistor

PTC thermistors primarily have the following three characteristics.

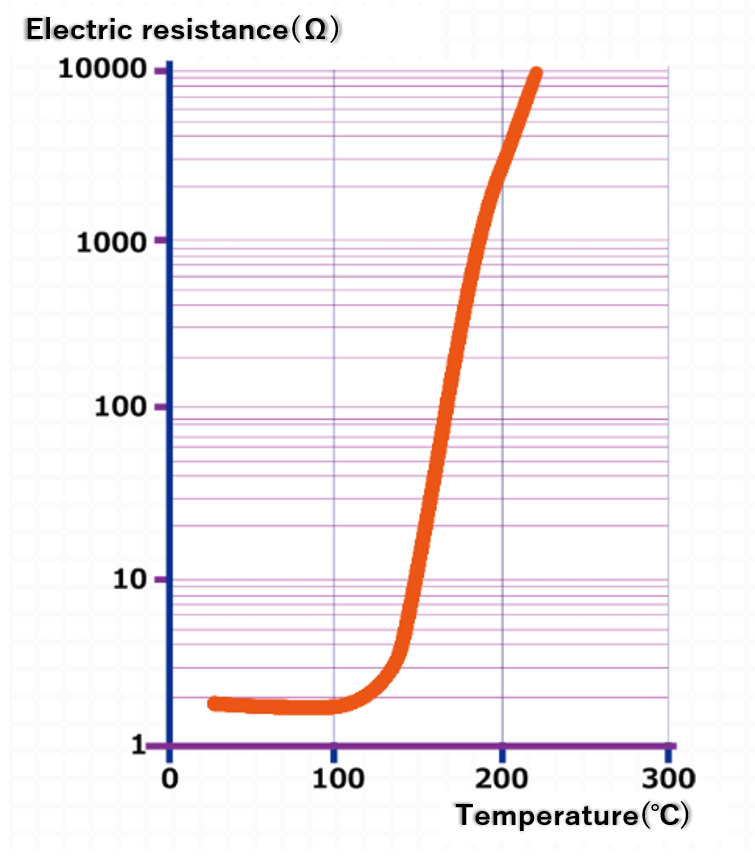

1.Using their resistance vs. temperature characteristics

The right figure shows relations between Resistance and Temperature of PTC Thermistor. The resistance value is almost constant from room temperature to Curie temperature and after reaching the Curie Temperature, the resistance value is to be increased quickly.

The constant resistance value at room temperature and Curie temperature are to be varied by material composition of PTC thermistor. According to the above characteristics PTC thermistor is to be used as detector for destroying of semiconductor part by heating problem and for overheating prevent from fire.

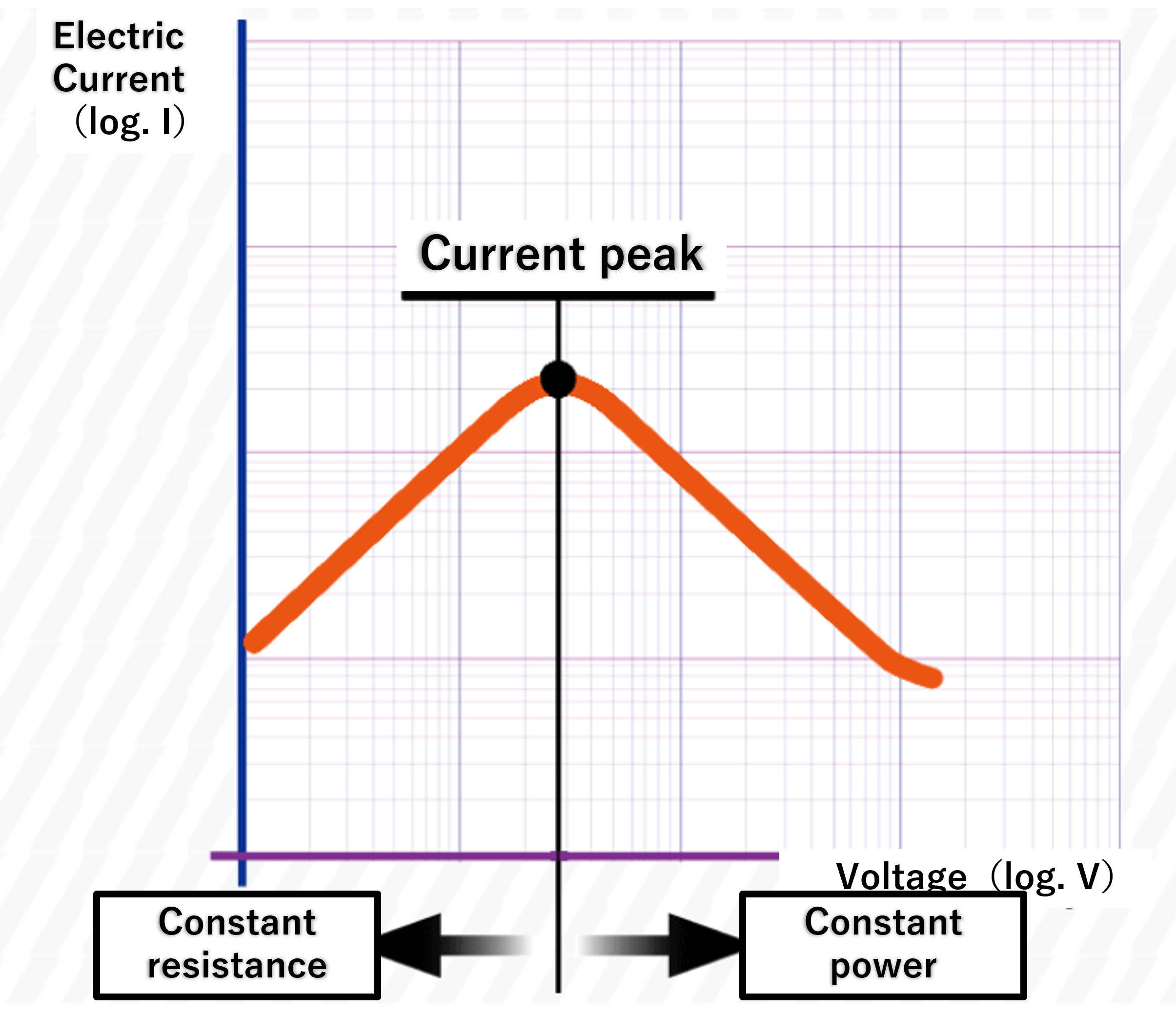

2.Using their static characteristics

The right figure shows typical relations between Current(I) and Voltage(V) of PTC Thermistor. The range of constant resistnace value is kept until reaching Curie temperature(Tc) (the maximum point of electrical current value) during electrical current value is increased by voltage rose, then the range of constant electric power is to be come. This feature is to be used for Heater and Part for over current protection.

The PTC thermistor for Heater is self-temperature control type and to be used under the range of the constant electric power(Wattage)not affected by environmental temperature and applied electric voltage. PTC thermistor has no switching noise, which is happened by use of Bi-metal, and is long-life type and is keeping constant temperature without any fluctuation Especially, our PTC thermistor is smaller size and can rise temperature quickly and make high power with low resistance value.

The PTC thermistor for Over current protection is to be used by sudden resistance value increasing just after Cury Temperature reached by over current applied. The thermistor is to be used similar to fuse but with resettable protection as many times as requested. Especially, our PTC thermistor for Over current protection has quick response ability by smaller size with low resistance value.

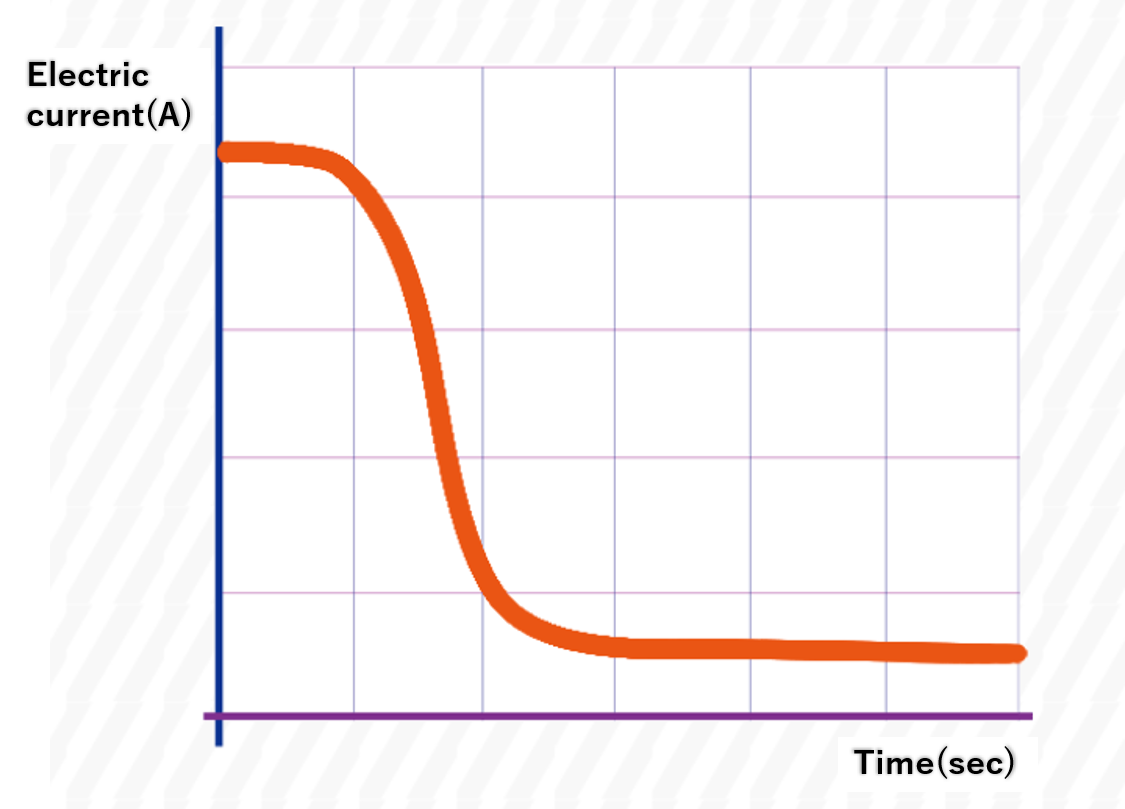

3.Using their dynamic characteristics

The left figure shows the relations between current and time after putting voltage. Just after Voltage, resistance value is small and current valueis rather big. After sometime passed, resitance value of PTC thermistor is to be increased by their self- heating performance, then Current value become smaller.

The above characteristics are to be used for motor starter and relay-delay circuit, etc..

MAXIMUM TECHNOLOGY Product Features

Manufacturing technology for low-resistance materials

Our Liquid -phase method, different from other makers, is providing sintered body with uniform particle size and grain boudary.World class low resistance value is to be provided by the uniform material and is making smaller size thermistor.

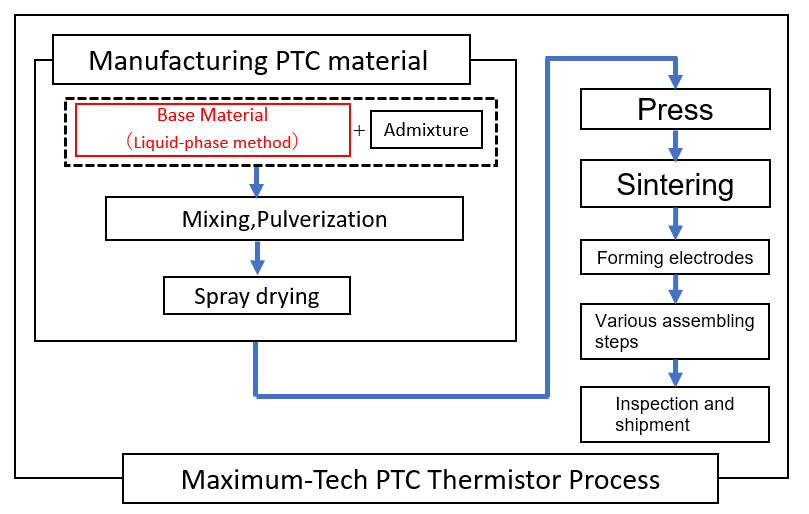

Our process flow for PTC Thermistor and its applied products is as follows:

- [Liquid-phase method]

Manufacturing PTC material powder - Press

- Sintering

- Forming electrodes

- Various assembling steps

- Inspection and shipment

PTC thermistor products

Overcurrent prevention PTC

PTC Heater

Lithium-ion battery heater

Applications of PTC Thermistors

PTC Thermistors are generally used as temperature sensors, and are also used for purposes such as overheat protection curent limitting by their characterristics. In Current Society, it is widely used to improve the safety for electirical and mechanical devices by smaller size and the performance which can be used repeatedly.

Home Appliances

PTC Thermistors can also be used for home appliances such as refrigerators and heat pump type air conditioners with PTC's characterrietics of over heating protection and temperature control. In addition, PTC thermistors are to be used for various applications such as power tools with motor to prevent from too much overheating and contrermeasure of overheating of batteries. And it can be used for smaller home appliances such as hair dryers with both functions of prevention of over heating and heater. It can be also used for overheating protection for battery chargers of mobile phone.

Industrial Equipment

It is used for supporting the operation of Industrilai equipment as over heating protection in its generators and motors to improve the life of equipment by reducing the load. It is used often and easily as heater for prevent blow-by gas and CCV from freezing in cold region, and it is especially used as smaller and without comlex control unit. And alsoPTCThermistors are used in a wide range application for industrilal equipment, such as in HVAC system wich control heating, ventilation, and air conditioning as temperature control unit.

Aerospace Industry

PTC Thermistors are used for cintrol temperature of devices to be used in harsh enviroments such as aircraft and outer space. PTC Thermistors which are small size and do not require complex control unit are suitable to use especially in equipment which is used under severe resrictions.

Lithium-Ion Batteries

It is used as contermeasure against overheating to reduce the risk of fire and explosion due to overheating of Lithium-Ion-Batteries used in various products. And the performance of lithium-Ion-batteries decrease in cold region but the battery is to be recovered by using PTC unit as heater as possible coutremeasure for cold region. The simple performance for heating control by passing electric current only is suitable to such equipment in cold regon.

Medical Devices

Also, it can be used for medical equipment which is required temperature control safely. It is expedted to use for madical equipment by utilization of protection from abnormal current and overheating and by wraming equipment safely. PTC heaters are heating components utilizing the characteristics of PTC Thermistors. PTC Thermistors are self-heated by passing electrisity. In addition, when it rises to a certain temperature, it can maintain the temperature. Utilizing this characteristics, PTC heaters areused as heating components. By utilizing the caharacteristics PTC thermistors, PTC heaters are more energy-saving, easy to control, and safer than the general heating components.

Contact Us

Feel free to reach out to us for any inquiries regarding our services or business. You can contact us via phone or through our online inquiry form.